An interview with Michael Pettersen, Shure Incorporated. Written for A Row of Trees Journal

More lies have been heard through the SM57 microphone than any other microphone in the world.

Michael Pettersen, Shure Incorporated

Shure Incorporated are the largest manufacturer of professional microphones in the world. They make wired microphones, headphones, earphones, conferencing equipment, pretty much all things audio. They also make wireless microphones and wireless in-ear monitors. If you think about what a microphone looks like, you are likely thinking about one of two Shure microphone designs; The Unidyne Model 55 or the SM58. The Unidyne Model 55 microphone has a, now iconic, front grill design associated with singers such as Elvis Presley. The Institute of Electrical and Electronics Engineers (IEEE) hailed the invention of the Unidyne as a technological milestone alongside a small number of other significant technological achievements that include the development of radio, Claude E. Shannon’s Information Theory, the breaking of the Enigma Code during the Second World War and the invention of the transistor.[i] The SM58 (and its sibling the SM57) are the most commonly used handheld vocal and instrument microphones in the world. The SM57 has been the microphone of choice for every President of the United States of American since Lyndon B. Johnson. As Michael Pettersen of Shure states, “more lies have been heard through the SM57 microphone than any other microphone in the world”.

Founded in Chicago, Illinois in 1925 by Sidney N. Shure, the Shure Radio Company, as it was initially known, sold AM radio kit components before becoming Shure Brothers Company in 1928 when Samuel J. Shure joined his brother in business. By 1929 Shure had become the exclusive distributor for a microphone manufacturer called Ellis Electrical Laboratories. By 1932 the company was building its own microphones, initially based on a very similar design to the Ellis products they were distributing. Shure released their first crystal microphone in 1935.

A crystal microphone? How can a crystal be a microphone?

When I first discovered a crystal could be used to make a microphone I was dazzled. I found some information about the history of crystal microphones at Shure on their website.[ii] In early March 2022 I filled out an online “contact customer support” form to ask for more information. Given the size of the company I was surprised to get a response the same day from Michael Pettersen, Director of Corporate History at Shure Incorporated (as it is now known). He had written the article about crystal microphones on the Shure website and shared my amazement that a crystal could be a microphone. Six months later and I am sitting inside the performance theatre at Shure’s headquarters in Niles, Illinois, talking about crystals, microphones, and all things Shure with Michael.

Mic Check

Parker: Michael Scott Pettersen was born in 1952 in Rockford, a city in northern Illinois. In his early years he became interested in the guitar, eventually graduating from the University of Illinois in Urbana with a degree in Music Theory and a Minor in History and Astronomy. He stayed in Urbana after graduating, working primarily as guitar tutor and trying to make it as a guitarist in his own right. Aged 23, in 1976, Michael applied for a job in sales at Shure and moved to Evanston, a suburb of the greater Chicago area, thinking he’d give it a shot. Now into his 47th year with the company Michael is the second longest serving member of staff currently working at Shure. Starting in sales, Michael explained how he has managed to keep things interesting for so long whilst working for only one company.

Pettersen: I’ve had multiple jobs within the company. I worked in sales, in marketing, in engineering, in application engineering, and advanced product planning and now historian. I have been able to move careers without moving company. Quite convenient!

Parker: The history around the invention of the microphone is knotty and not without controversy. Inspired by Charles Wheatstone’s description of a microphone effect to refer to a mechanical sound amplifier, British-American David Edward Hughes coined the term ‘microphone’ when he developed a carbon based transmitter which could amplify a voice. He never patented his invention. German-American Emile Berliner submitted a patent caveat in the United States Patent Office for his invention of the “loose-contact” transmitter in 1877 having designed it in his bedroom. The Bell Telephone Company who had the year previous launched their new telephone found out about the caveat and Bell’s assistant Thomas Watson visited Berliner. Berliner was inspired to make the transmitter having seen Bell’s telephone and noticed that Bell’s method for sound transmission was comparatively crude; suspending a diaphragm over a pool of electrified mercury. Berliner’s design using a diaphragm and electrified carbon ball was safer and more reliable.[iii] On his visit, Watson was so impressed by what Berliner had designed, whilst in his bedroom, that the company purchased his design and employed Berliner with immediate effect. The American Thomas Edison claimed to have a similar carbon telephone design, and engaged in a series of public and legal contestations against Berliner and Hughes in what was at the time described as an “ill-judged attack” by historian of technology Count Théodore Du Moncel.[iv] Edison has been accused for being a “patent troll” with a “habit of taking other people’s ideas and claiming credit/monopoly for them after slight modifications” and was involved in more than a handful of high profile patent battles, as was Alexander Bell.[v] Half a century passed between Berliner’s invention and when the Shure Brothers started working in the microphone business in 1929. By this time carbon microphones such as those designed by Hughes and Berliner were not the only type of microphone in existence but they were still the most common sold at both consumer and professional levels.

Pettersen: The first microphones that Shure distributed were in 1930, made by Ellis Electrical Laboratories. They were carbon microphones. The first microphone designed and manufactured by Shure, the Model 33N came out in 1932 and was a two button carbon microphone which looked a heck of a lot like the Ellis microphones!

Carbon microphones have a tiny bowl full of carbon granules for lack of a better term. A diaphragm presses down on and releases those granules which in turn effectively creates a variable resistor. When the carbon granules are put together there is less resistance and when they are further apart there is more resistance. If you run a DC current through that, the resistance variations you get by the diaphragm pressing in and out creates an AC voltage output. An audio signal. That is how it works. Carbon microphones don’t sound very good. But they are OK for voice and speech intelligibility. They were used in telephones right up until the 1970s. One thing about carbon microphones is that they are really rugged. You cannot destroy a carbon microphone. If someone buries a carbon microphone and we dig it up in a thousand years from now, you could brush it off, shake the carbon granules loose and it’ll work just fine!

Parker: We’re sat on the stage of the performance theatre at the current headquarters for Shure Incorporated which is just outside the Chicago suburb of Niles. In 2003 the company moved into this impressive building designed by the architect Helmut Jahn, who also designed the iconic Sony Center in Berlin. Michael explained how its previous occupants had gone bust and the building was going for a song. Shure’s facilities in Niles are extensive, although their mass production facilities are located elsewhere; in Mexico and China.

In addition to the sound-proofed performance theatre, the building has multiple floors of office space, a small visitor’s museum and a huge technical engineering department. I’m only allowed to see some of the engineering spaces as much of the innovation and design labs are closed off for non-staff visitors without an NDA. There is a full size professional grade recording studio and live room, built onto an internally carved out floating foundation to avoid any external acoustic vibration. There are multiple rapid prototyping labs and workshops, two anechoic chambers, two RF (radio frequency) shielded faraday cage test suites, temperature and humidity tests booths, and a ‘roadie’ test machine which can simulate long periods on the road, with time programmable variable environmental conditions and vibrations. My personal favourite is the ‘mic drop’ test machine which has a super slow motion camera poised to monitor different controlled drops of equipment.

Pettersen: From 1943-1945 our primary business was producing microphones and headphones for the Allied forces; the United States, Russia, and United Kingdom. We had to build products to a much higher standard; what you call MIL-SPEC or military specification. That was the reliability end of the product. If a microphone or headphone failed for the military you might lose a person, a platoon, who knows what might happen! We started building things to military spec and when the war ended, S.N. Shure (the company founder) made a momentous decision. He said ‘well this MIL-SPEC stuff makes better products and they last better, they’re more reliable, more durable, and we have less returns. So let’s continue to build consumer products using military spec’. We still do that to this day. The torture chambers that we put things through here, environmentally, physically, and so forth are why our equipment is so reliable. I personally have Shure products bought in the 1970s and they still work just fine. Most of the products we have in our company archive still work just as well.

Parker: On the previous day, Michael took me to meet his colleague Julie Snyder, the Shure Librarian and custodian of the Shure Archives. Located between a range of industrial design workshops the archives include historic documentation and products ranging from Ronald Reagan’s presidential podium, a heavy door that was used in their previous Evanston headquarters’ anechoic chamber, to countless samples of their historic product collection including condenser, dynamic, ribbon and carbon based microphones.

Pettersen: The condenser microphone was invented by Edward C. Wente who worked for the Research Laboratory of the American Telephone & Telegraph Co. and Western Electric Co., Inc. He came up with the concept in 1917 whilst working on a PhD at Yale.[vi] Condenser microphones should really be called capacitor microphones. Condenser was the term used for a capacitor back in the day and for some reason we’re still using that term now. With a condenser you have a diaphragm with a thin coating of gold on it and a conductive back plate which has a voltage on it. There is small gap between the two sides. As the diaphragm moves in response to sound, it changes the airspace which gives you a difference in capacitance voltage.

Dynamic microphones are effectively loudspeakers in reverse. You have a diaphragm with a voice-coil on its axis, or a coil wire which is suspended in a magnetic field, and as that diaphragm bounces up and down, the voice coil cuts through the magnetic lines and gives you an output level. That’s it! Shure is most known for its dynamic microphones. There are also microphones which are just a variation of a dynamic microphone. A ribbon microphone works where instead of a voice coil you have corrugated ribbon which acts as the diaphragm and the voice coil at the same time suspended in a magnetic field.

There are also MEMS (Microelectromechanical systems) which are a relatively new microphone technology but are in principle just very small condenser microphones. We don’t make them here. Those are the primary ways that microphones are made now and really have been for the last hundred years, except for the MEMS.

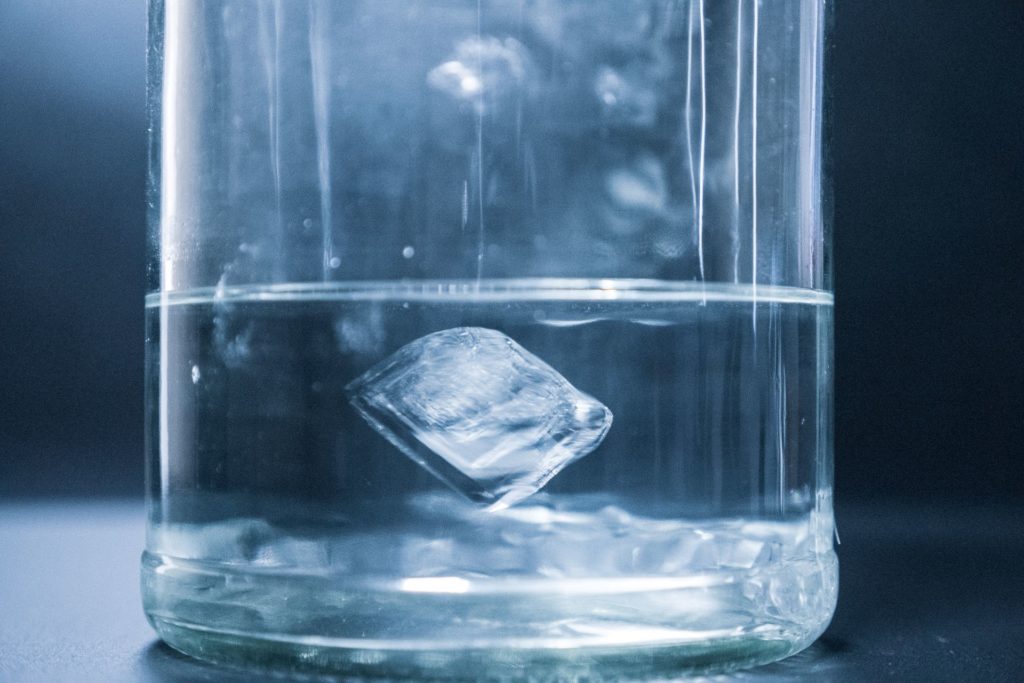

Parker: The fundamental purpose of any microphone design is to be able to detect the input of an external vibration, or signal, and convert that vibration into an alternating current in a process called transduction. In addition to the condenser, carbon, and dynamic systems there is also another microphone technology which uses a piezoelectric crystal as the medium to generate an alternating current. The crystal used by Shure microphones is potassium sodium tartrate tetrahydrate (KNaC4H4O6·4H2O); commonly known as Rochelle salt. Rochelle salt is a synthesised crystal that was first created by a family of apothecaries living in La Rochelle on the Atlantic Coast of France from 1657-1736. Sold originally under the name ‘Sel Polychreste’ or ‘salt of many virtues’, the Seignette family kept the chemical formula of their crystal a close secret for over sixty years. During the Reformation period the family experienced frequent aggression from the Catholic state who refused to recognise their licence as apothecaries because of their Huguenot protestant background. It took a royal decree from Louis XIV to validate the young Elie Seignette as a recognised and licensed apothecary, following the King being so impressed with the magic crystals.[vii]

Often referred to as Seignette salt, the crystals were consumed as a mild relaxant and laxative, and exported across Europe and North America where the familiar name of Rochelle salt took hold. Once the crystal formula was worked out by other chemists, further experimentation took place. The crystal was found not only to be a useful digestive aid but also worked as a reducing agent for obtaining silver mirrors on glass instead of toxic mercury. A detailed account of the chemical history of Rochelle salt was written by Henry Sjoerd van Klooster (1884-1972), a Dutch-American chemist and academic.[viii]

After two centuries of use, an electrifying discovery was made about Rochelle salt by the brothers Pierre and Jacques Curie in 1880. It was piezoelectric. The word “piezo” is derived from the Greek word meaning “to press”. Piezoelectricity is “pressure electricity”, or electrification produced by mechanical pressure. Alongside tourmaline, quartz and a number of other crystals, Rochelle salt was recoded as being, by orders of magnitude, the most powerful piezoelectric crystal. A former student of Pierre Curie’s named Paul Langevin began work on the first piezoelectric transducer ‘hydrophone’ using Rochelle salt during the First World War in an attempt to detect German submarines. Using just a simple salt, his work became the foundation for sonar. After the United States was drawn into the War, two researchers, Walter Guyton Cady and Alexander McLean Nicolson both began further experimentation with Rochelle salt and piezoelectricity as a means for transducing energy and as a listening tool.[ix] Essentially, you can create an AC current by vibrating a crystal, and the Shure engineers explored this potential to full effect.

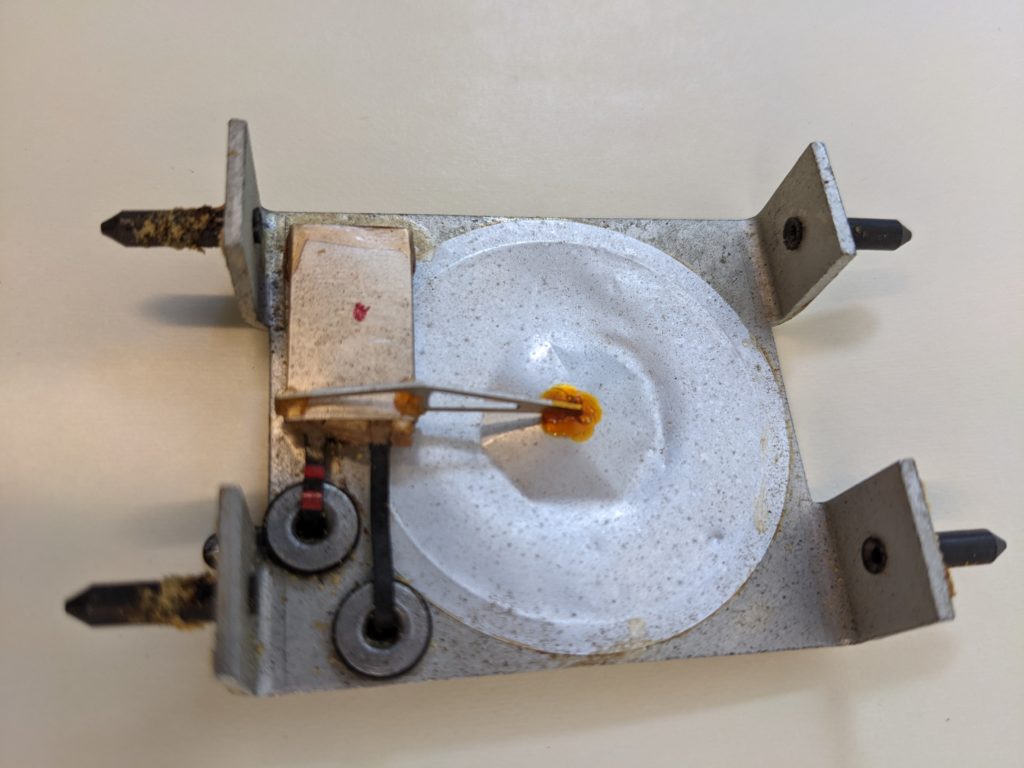

Pettersen: Why look at a salt? I have no idea! They just figured ‘let’s look at a salt’ and there you go! Shure started purchasing Rochelle salt crystals from a company called Brush Development Corporation who from the mid-1920s held all of the US patents for industrial scale Rochelle salt production. Our first microphones using crystals came out in 1935. We took a very thin slice of a crystal, maybe the size of your fingernail, held it down at one end and flexed it at the other and this gave us an AC output voltage.

The most significant engineer that Shure had was a man named Ben Bauer, originally Benjamin Baumzweiger, a migrant from Odessa in what is now Ukraine. He came to work with us in 1936 aged 23 and left in 1957. He was a real genius. His big breakthrough was what’s called the Uniphase acoustical system. For lack of a better term it is an acoustic network that goes inside of a microphone and allows a single element of a microphone to be directional. So a microphone that listens better in one direction rather than another. This is a gross simplification of some advanced mathematics and engineering that revolutionised microphone technology! The first Uniphase microphone that we released was the Model 730A “Uniplex” Crystal Microphone. A few months after that came out, the Unidyne Microphone Model 55 came out which is the Elvis microphone. This is a moving coil dynamic microphone. The 730 didn’t last very long because sound-wise, the Unidyne moving coil just sounded a lot better. More low-end, wider frequency range and so forth.

We made crystal microphones and crystal phonograph cartridges too. There were crystal earphones but we didn’t make them. You can go back to the 1920s and 1930s and there were also crystal headphones. We also made some accelerometers; devices that measured vibrations of machines and so forth. We made a contact mic that you could put on a guitar. We also made a stethoscope (Stethophone) for listening to heart sounds. Anything that was vibrating that you needed to turn into an electric signal, we turned to crystals!

Parker: The Second World War resulted in Shure focussing heavily on their MIL-SPEC requirements. Many of the products they made were focussed on speech intelligibility and ruggedness for combat zones which resulted in many carbon and dynamic microphone innovations. The crystal transducer fell somewhat to the wayside.

Pettersen: The problem with crystals is that they do tend to fail over a period of time but we can go back and pull a carbon microphone out from 1930 and it will work fine. The issue with salts is that they dissolve. High humidity and high temperature were prominently featured as warnings on all of our user guides for crystal microphones. The high temps maybe made the physical structure or lattice to change or crumble. We made crystal products at Shure for 35 years but not anymore. By 1970 we got rid of the last crystal microphone. Crystal had been replaced by Barium titanate which is a type of ceramic compound which effectively does what a crystal does without the problem with temperature and moisture. It is an example of where material science made the crystal obsolete.

There are still harmonica players that love some of our old crystal style microphones. They are bullet shaped microphones that fit in the palm of your hands and these harmonica players love the way the crystal distorts when you overblow into it. But of course, you are blowing hot air and moisture directly at the crystal. So probably not a great idea!

It is an unusual technology which has me intrigued. How does a piece of salt give you an audio output? I think that’s a weird aspect; to just think about that. Who first thought to try to make that thing happen? As a historian I am interested in what they sound like. We have some working ones in the archives and I was quite surprised when listening to them. They don’t sound bad at all. Not much low end but the high end is quite nice. Very intelligible. Right now, there seems to be a few people here at Shure taking an interest in crystal microphones. I don’t see it having a comeback but it served us well as a primary transduction technology that was replaced mainly by condenser and moving coil dynamics.

Parker: In the height of the UK lockdowns imposed because of the Covid-19 pandemic, like many others, I found myself trying to find things to do around the home. I wondered how the Seignette family had first come across their crystal. I remembered as a child that there was a science class where we grew electric blue copper sulphate crystals in a petri dish. Organic piezoelectric crystals such as tourmaline or quartz take thousands of years to form under extreme hydrothermal conditions featuring intense pressure and high temperature. Synthetic Rochelle salt crystals on the other hand can be grown in a much shorter period of time. You can grow your own Rochelle salt crystals using three simple ingredients: baking powder, cream of tartar and water. It is the tartaric acid, a crystalline residue that forms from the lees during the fermentation process of wine that was the secret, undiscovered ingredient, to Rochelle salt. There are a number of excellent and detailed guides on how to grow crystals that range from detailed scientific analysis down to electrical hobbyist.[x] It is a relatively simple process in essence but for the most impressive effects one must continue to play at managing a balance between temperature and saturation of a solution of water and dissolved Rochelle salt. I haven’t successfully made a crystal microphone just yet but my visit to Shure Microphones has inspired me to keep trying. Not only because I find the concept of a microphone made from a crystal to be fascinating but because Michael’s passion for audio and for Shure as a company was truly inspirational.

Pettersen: I have been really fortunate because I found a company that really fits my philosophy of life. My interests. It’s hard to find someone who has been working for 47 years and still can’t wait to get into work each day. And that is how I feel. My father worked in construction and he was exhausted from work every day because it is hard, physical work. I have had almost the opposite. When the weekend comes around, I am like… “oh… it’s the weekend…” because I just want to get back to work. I really enjoy it that much.

Shure is a company that’s run for profit, but also run for the benefit of charity which is pretty unique. What happens is that at the end of the year, rather than taking all the money and sharing it out to the executives—and the executives make money as we all do—most of the money goes out to charity for humanitarian purposes and educational purposes. There are some other companies that operate like Shure such as Lego, Rolex, Bose and the Carlsberg brewery, but they are few and far between. It’s nice to come into work, make products which are seen on television all the time, make products which you see being used by artists that I like, some that I don’t like! But also know that we are doing some good for the world. That’s a pretty good way to work and to spend your career.

Parker: And a pretty good staff discount?

Pettersen: Oh yeah we get discounts too!

Acknowledgements

This interview was made possible thanks to funding and support from Oxford Brookes University, the Arts and Humanities Research Council’s International Placement Scheme, the Huntington Library in California, and Shure Incorporated.

Endnotes

[i] ‘Milestones: List of IEEE Milestones’, Engineering and Technology History Wiki, 9 December 2020, https://ethw.org/Milestones:List_of_IEEE_Milestones.

[ii] Michael Pettersen, ‘The History of Crystal Microphones and Artifacts from the Shure Archives’, Shure, 2020, https://www.shure.com/en-US/performance-production/louder/the-history-of-crystal-microphones-and-artifacts-from-the-shure-archives.

[iii] Frederic William Wile, Emile Berliner: Maker of the Microphone (Indianapolis: The Bobbs-Merrill Company, 1936).

[iv] Théodore Du Moncel, The Telephone, the Microphone and the Phonograph (New York, NY: Harper, 1879), 144, http://archive.org/details/telephonemicrop01moncgoog.

[v] Roy Schestowitz, ‘The Truth About Thomas Edison and New Species of Patent Trolls’, Techrights (blog), 3 September 2010, http://techrights.org/2010/09/03/patent-office-icon-shamed/; Seth Shulman, The Telephone Gambit: Chasing Alexander Graham Bell’s Secret, Illustrated edition (New York, NY: W. W. Norton & Company, 2009).

[vi] E. C. Wente, ‘A Condenser Transmitter as a Uniformly Sensitive Instrument for the Absolute Measurement of Sound Intensity’, Physical Review 10, no. 1 (1 July 1917): 39–63, https://doi.org/10.1103/PhysRev.10.39.

[vii] H.S. van Klooster, ‘Three Centuries of Rochelle Salt’, Journal of Chemical Education 36, no. 7 (July 1959): 314, https://doi.org/10.1021/ed036p314.

[viii] van Klooster.

[ix] W. G. Cady, ‘Nature and Use of Piezoelectricity’, Electrical Engineering 66, no. 8 (August 1947): 758–62, https://doi.org/10.1109/EE.1947.6443660.

[x] Kjellgren Bengt, Method of producing piezo-electric crystals, United States US1906757A, filed 19 May 1928, and issued 2 May 1933, https://patents.google.com/patent/US1906757A/en?q=crystal&assignee=Brush+Dev+Co&country=US&page=4; Walter Guyton Cady, Piezoelectricity: Volume One: An Introduction to the Theory and Applications of Electromechanical Phenomena in Crystals, Illustrated Edition, vol. 1, 2 vols (Mineola, New York: Dover Publications Inc., 1946); A. M. Nicolson, ‘Piezo-Electricity or “Speaking Crystals”’, Electrical Experimenter, December 1919; Charles W. Clifford, ‘The Growing of Rochelle Salt Crystals for Radio Experiments’, Journal of Chemical Education 16, no. 2 (February 1939): 86, https://doi.org/10.1021/ed016p86; Bengt R. F. Kjellgren, Method of growing a rochelle salt crystal, United States US2483647A, filed 31 October 1947, and issued 4 October 1949, https://patents.google.com/patent/US2483647A/en?q=crystal&assignee=Brush+Dev+Co&country=US&page=3; William J. Millard, ‘Singing Crystals’, Elementary Electronics, 1968; MakerIan, ‘Make Rochelle Salt’, Instructables, accessed 19 January 2021, https://www.instructables.com/Make-Rochelle-Salt/.